Trinity Engineering Offers an integrated set of services that turns ideas into reality

For over 45 years our mission has been to meet or exceed our clients expectations in the design fabrication, and installation phases of every job. Our skilled and experienced staff builds client relationships that translate into repeat business and referrals. As a trusted team partner, Trinity Engineering is dedicated to the success of every project.

Fundamentally, the Trinity Team is compromised of a group of professionals that excel in problem solving and thinking outside the box. Each team member is dedicated to continuing our legacy of excellence.

From the design phase through the installation phase, each project has a continuous flow of choices and options. We are inspired by these challenges and thrive off creating solutions that fit our client’s needs and budget.

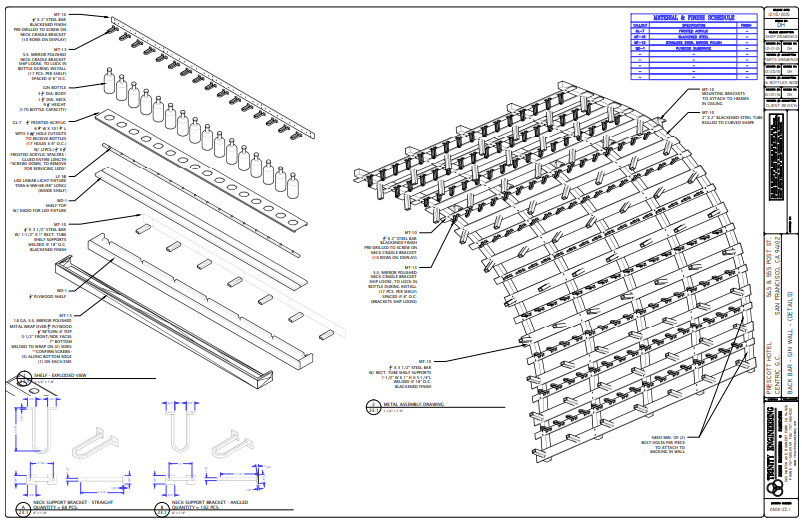

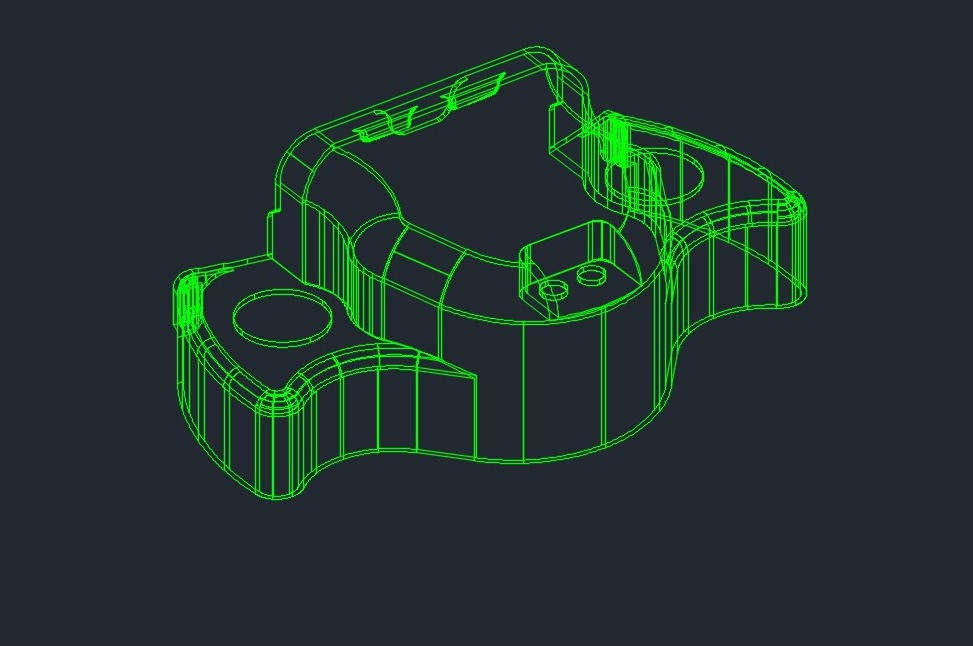

Whether a design concept originates within Trinity Engineering or we prepare design intent plans for production applications, our staff considers each detailed element of the job without losing sight of the project as a whole.

Site surveys and routine inspections by project managers help prevent costly communication breakdown and allows us to prepare for unseen or changed conditions.

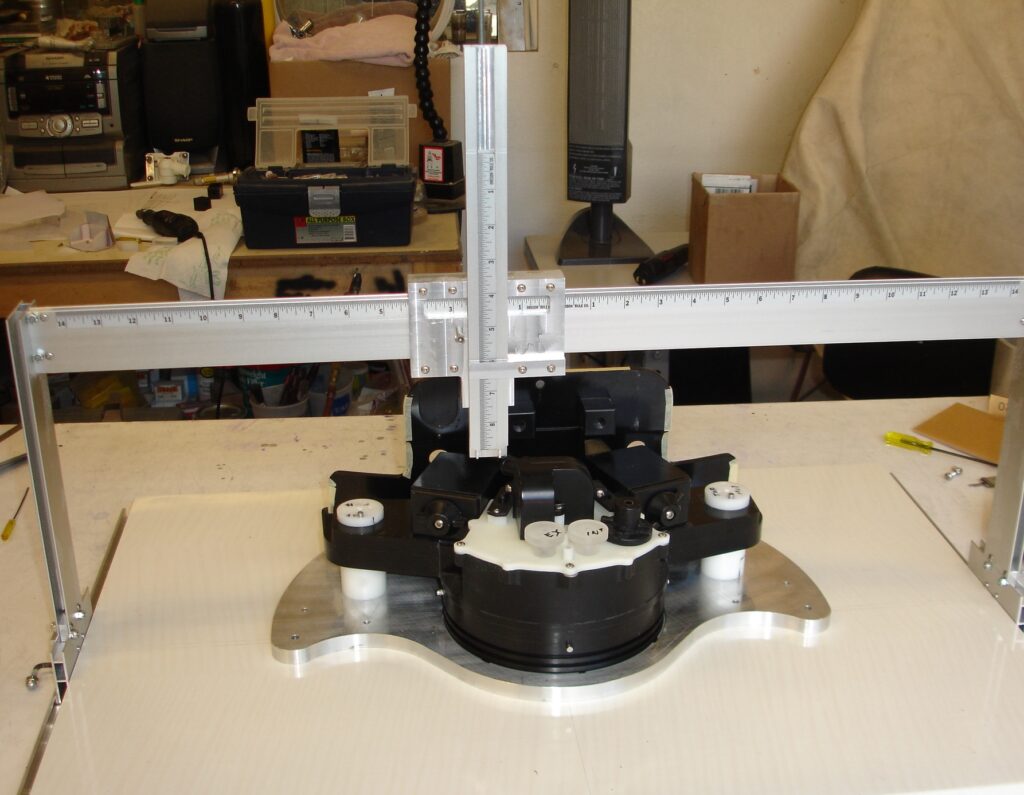

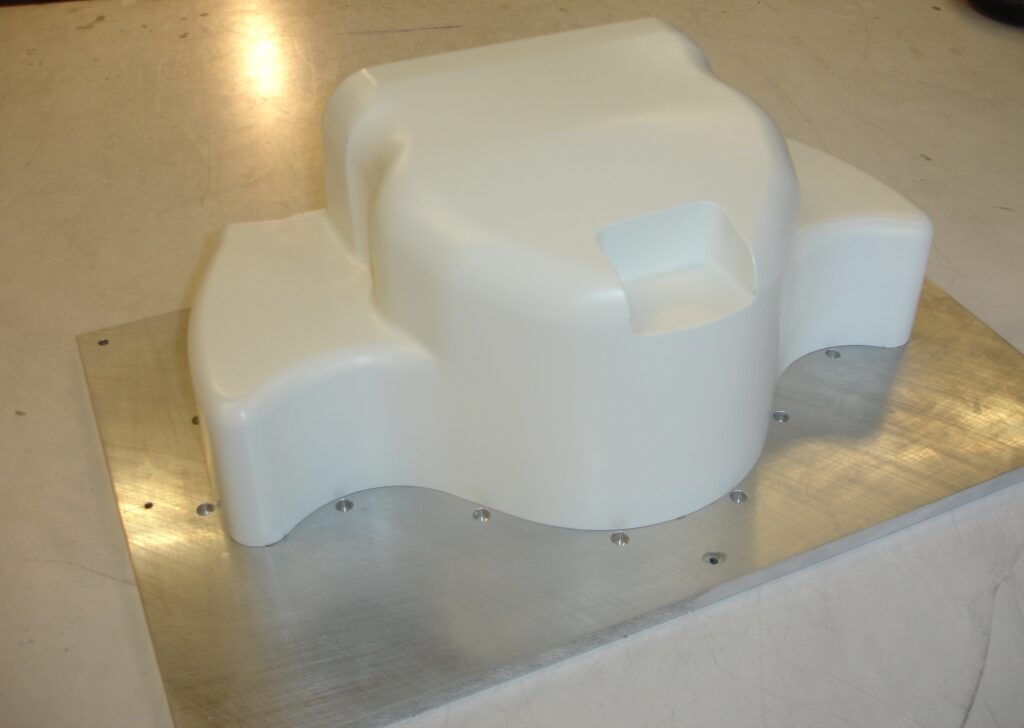

At Trinity Engineering our philosophy is to utilize practical applications of art and science to create the highest quality of work available. Our technicians are artisans on their particular craft. They strive to create unique expressions from both traditional and technological advanced methods.

Our skilled crew has experience across multiple disciplines of fabrications as well as being familiar with a wide spectrum of diverse materials. Although the core of our portfolio is centered in wood working. Trinity Engineering has on site talent that includes metal work, glass, laminates, veneers, acrylic, solid surfaces, and formulated resins.

Many projects include unique lighting elements, use of large scale graphics, and LED panels. Trinity Engineering’s and blasting booth and professional spray booth enables our crew to create a variety of textures and finishes that are appropriate for each project.

Prior to shipping, large scale projects can be fully assembled to gaurantee proper fit and orientation.

Trinity Engineering has a passion for prototype projects They are challenging, fun and ultimately, the most satisfying.

Custom builds that start from a blank slate are the spirit and foundation of invention. our esign and development process allows our clients to start with only a “napkin sketch” concept that is transformed into a one of a kind three dimensional experience.

Over the years Trinity Engineering has collaborated on the development of prototypes outside the world of custom millwork and store fixtures. Some if these items have included various support structures, locks and specialized hardware. Large scale projects have included motorcycle design and scuba equiptment.

Trinity Engineering operates on its own freight delivery for local projects. This allows flexibility to work around construction schedules.

National and International projects may require custom crates to store and transport product. Trinity coordinates crate construction and storage for product until the desired ship date.

We are on the job until our clients are satisfied. Our team can either install the job personally or work with union crews until it is finished. Our Project managers make periodic site inspections and work with general contractors to be sure every detail of the project has been addressed.

Want More Information?

Contact us for more information about what we can do for you and your business.